simulation

The LSP simulation team is developing a universal and anisotropic simulation platform with three simulation modules:

FEM (finite element modeling)

PTM (percolation threshold modeling)

ENM (modeling of electrical networks).

After years of modification and update, the simulation platform contains the following functions:

Anisotropy (orientation)

High flexibility: The filler geometry and orientation distribution can be manually set

High degree of automation: The simulation platform will detect if the result is reasonable, for abnormal experimental results or unexplained interruptions, the simulation platform will send a report to the experimenter.

High efficiency: With the same size of mesh and computing environment, our platform only needs 1/3 the time of former simulation programs.

High accuracy: all parameters and results can be specified with up to 12 decimal places.

Very low error rate (less than 0.01%).

The simulation team also did some analysis on the finite element analysis algorithm.

For any further questions about the academic exchange, you can contact the responsible person the simulation research group: Guanda Yang (guanda.yang@fau.de)

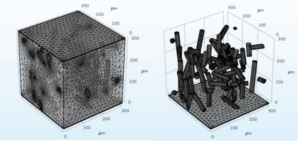

Figure 1, A relatively rough mesh which can quickly get the calculation result, with deviation 7,6%

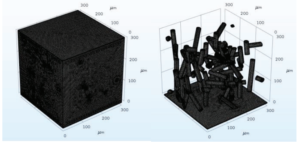

Figure 2, A fine mesh which needs more computational cost to get the calculation result, with deviation about 3,1%